Pneumatic systems are widely employed in various industries due to their efficiency, simplicity, and cost-effectiveness. These systems rely on the power of compressed air to perform tasks such as controlling valves, driving cylinders, and operating various mechanical components.

At the heart of these systems are pneumatic actuators, critical devices that convert the energy stored in compressed air into mechanical motion. In this article, we explore the importance, types, and applications of pneumatic actuators in pneumatic systems.

Understanding Pneumatic Actuators

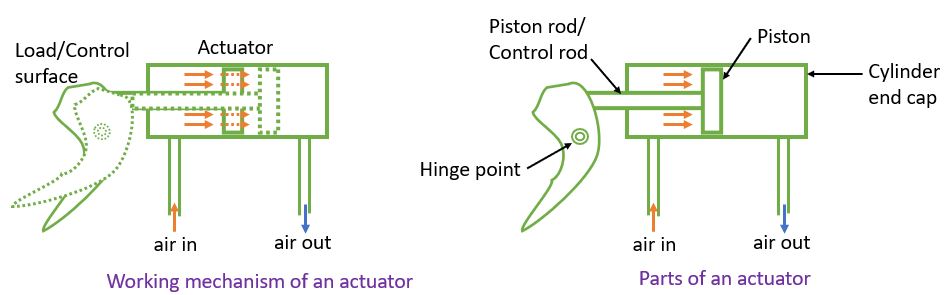

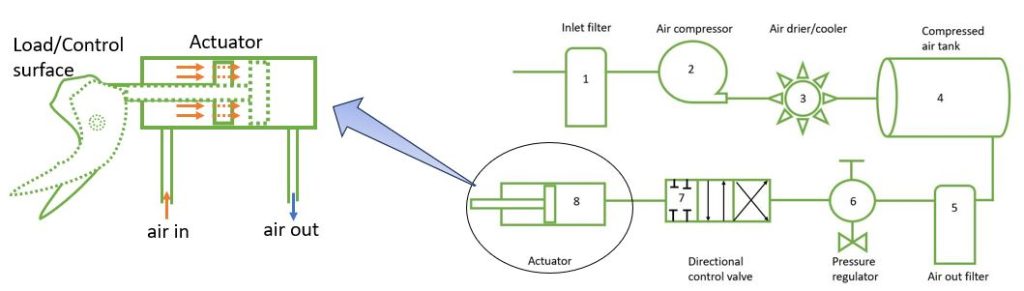

Pneumatic actuators are devices that use compressed air to generate motion, transforming the potential energy of the air into kinetic energy to perform mechanical work. These actuators play a crucial role in pneumatic systems, providing a means to control and manipulate various processes.

Compressed air from the pneumatic source is supplied to the pneumatic actuator through filter and various control valve. Pressurized air can be directed into the actuator cylinder from rod end or head end depends on which direction the control surface/load need to be moved. The direction of the pressurized air flow is controlled by the directional control valve.

Types of Pneumatic Actuators

Pneumatic actuators come in various types, each designed to fulfill specific requirements in different applications. Here are some common types of pneumatic actuators:

Pneumatic Cylinders:

Pneumatic cylinders, also known as air cylinders or pneumatic linear actuators, are the most common type. They convert compressed air into linear motion. The basic design includes a piston inside a cylinder, and when air is supplied to one side of the piston, it moves, causing the rod attached to it to extend or retract.

Rotary Actuators:

Rotary actuators convert linear motion into rotary motion. These actuators are suitable for applications where a rotary movement is required. They are often used in tasks such as turning valves, controlling dampers, or positioning components in a rotary manner.

Diaphragm Actuators:

Diaphragm actuators use a flexible diaphragm to generate motion. When air pressure is applied to one side of the diaphragm, it flexes, causing the actuator to move. Diaphragm actuators are commonly used in applications where cleanliness and leak-tightness are crucial, such as in the pharmaceutical and food industries.

Vane Actuators:

Vane actuators, also known as rotary vane actuators, use a vane or blade that rotates within a housing. The motion of the vane is driven by compressed air, resulting in rotary output. These actuators are suitable for applications that require a compact and lightweight solution for rotary motion.

Bellows Actuators:

Bellows actuators utilize a flexible bellows-like structure to generate motion. When air is introduced into the bellows, it expands or contracts, causing the actuator to move. Bellows actuators are often used in applications where a long stroke and high force are required.

Rack and Pinion Actuators:

Rack and pinion actuators convert linear motion into rotary motion using a toothed rack and a pinion gear. When compressed air is applied, the rack moves, rotating the pinion and producing rotary output. These actuators are commonly used in applications like valve control.

Piston Actuators:

Piston actuators use the motion of a piston to generate mechanical work. Compressed air is supplied to one side of the piston, causing it to move and produce linear or rotary motion depending on the design. Piston actuators are versatile and can be found in various industrial applications.

Guided Rodless Actuators:

Guided rodless actuators feature a piston enclosed in a cylindrical housing with guidance systems to prevent rotation. These actuators are suitable for applications where a long stroke is required without the need for a traditional rod extending from the cylinder.

The choice of a pneumatic actuator depends on the specific requirements of the application, including the type of motion needed, space constraints, and environmental considerations.

Applications of Pneumatic Actuators

Manufacturing and Automation:

Pneumatic actuators are extensively used in manufacturing and automation processes. They power robotic arms, conveyor systems, and various assembly line components, providing reliable and precise motion control.

Valve Control:

Pneumatic actuators play a vital role in controlling valves in industrial processes. They are commonly employed in applications where quick and precise valve movements are required, such as in chemical processing plants and water treatment facilities.

Material Handling:

Pneumatic actuators are crucial in material handling systems, where they facilitate the movement of goods on conveyor belts, lift platforms, and other equipment. Their ability to deliver consistent and controlled motion makes them ideal for such applications.

Advantages of Pneumatic Actuators

Cost-Effectiveness:

Pneumatic systems, including their actuators, are generally more affordable to install and maintain compared to other power transmission systems.

High Power-to-Weight Ratio:

Pneumatic actuators offer a high power-to-weight ratio, making them suitable for applications where lightweight and efficient components are essential.

Rapid Response and Precise Control:

Pneumatic actuators provide rapid response times and precise control, making them well-suited for applications that require quick and accurate motion.

Conclusion

Pneumatic actuators are integral components in pneumatic systems, driving efficiency and reliability in a wide range of industrial applications. Their ability to convert compressed air into controlled mechanical motion makes them indispensable for tasks ranging from manufacturing and automation to valve control and material handling.

As industries continue to seek efficient and cost-effective solutions, pneumatic actuators will likely remain a cornerstone of pneumatic systems, contributing to the advancement of various sectors.