Pneumatic systems are widely utilized in various industries for their efficiency and reliability in controlling mechanical processes. These systems rely on the precise control of air pressure to perform tasks such as actuating cylinders, controlling fluid flow, and managing automation processes. One critical component that plays a pivotal role in pneumatic systems is valves.

Pneumatic valves in pneumatic systems act as control devices, regulating the flow of compressed air to achieve specific functions. In this article, we will explore different types of valves commonly used in pneumatic systems and their unique applications.

Different types of pneumatic valves

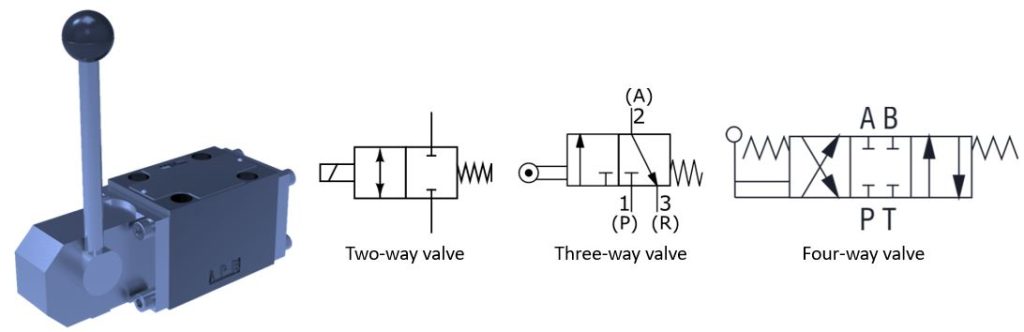

Directional Control Valves

Directional control valves are fundamental to pneumatic systems as they determine the direction of airflow. These valves include:

- Two-way valves: Also known as on/off valves, they control the flow of air in either an open or closed position.

- Three-way valves: These valves have three ports and can divert airflow to one of two possible paths.

- Four-way valves: Essential for controlling double-acting cylinders, these valves have four ports, enabling precise control over the airflow direction.

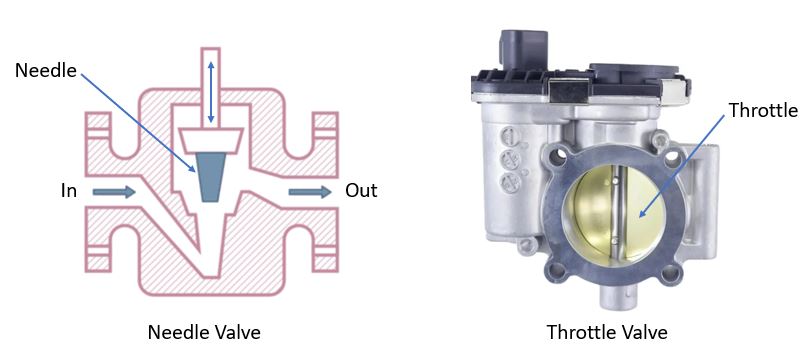

Flow Control Valves

Flow control valves manage the rate of airflow within a pneumatic system. Common types include:

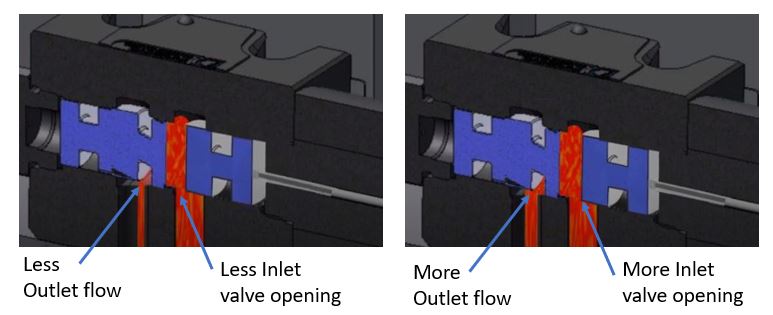

- Needle valves: These valves allow for fine adjustments in airflow by regulating the size of the opening through which air passes.

- Throttle valves: Also known as meter-out or meter-in valves, throttle valves control the speed of an actuator by adjusting the airflow entering or exiting the system.

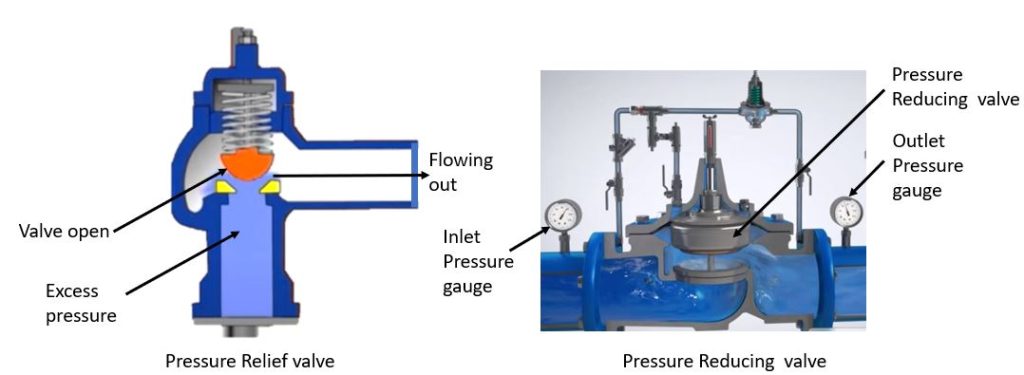

Pressure Control Valves

Pressure control valves maintain optimal pressure levels within a pneumatic system. Key types include:

- Pressure relief valves: Protect components from excessive pressure by releasing excess air when the pressure exceeds a set limit.

- Pressure reducing valves: These valves maintain a constant lower pressure in a specific part of the pneumatic system.

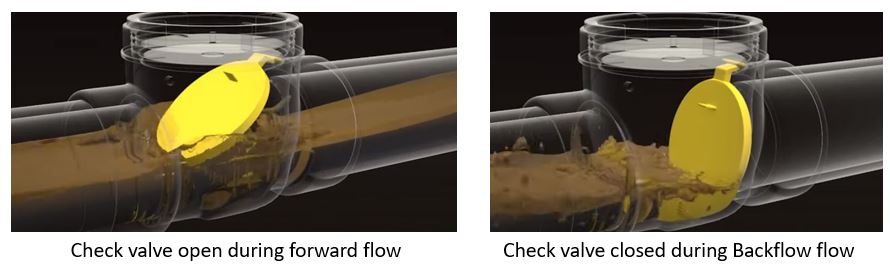

Check Valves

Check valves, or one-way valves, permit airflow in one direction only, preventing backflow. This is crucial in applications where maintaining pressure in a specific direction is essential.

Proportional Valves

Proportional valves offer precise control over airflow proportionate to the input signal. These valves are crucial in applications requiring accurate and variable control, such as in robotics and automation.

Solenoid Valves

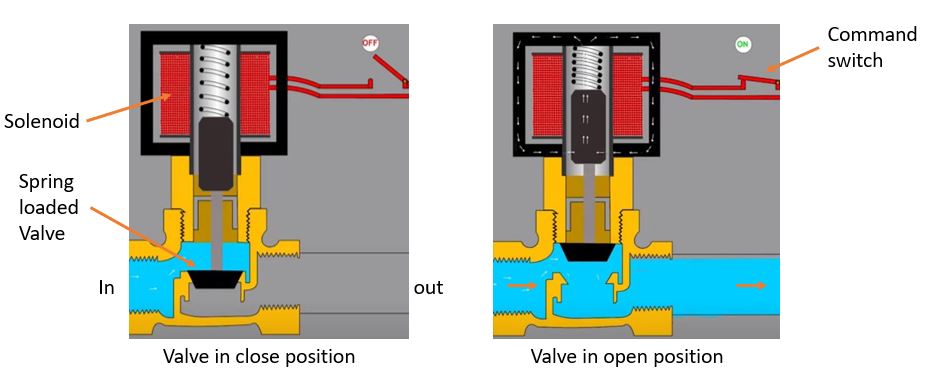

Solenoid valves are electrically controlled valves that use an electromechanical solenoid to control the flow of air. They are widely used for rapid and reliable on/off control in various pneumatic applications.

Pilot Operated Valves

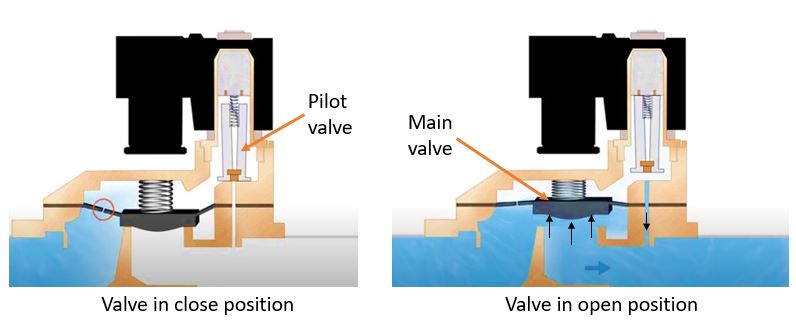

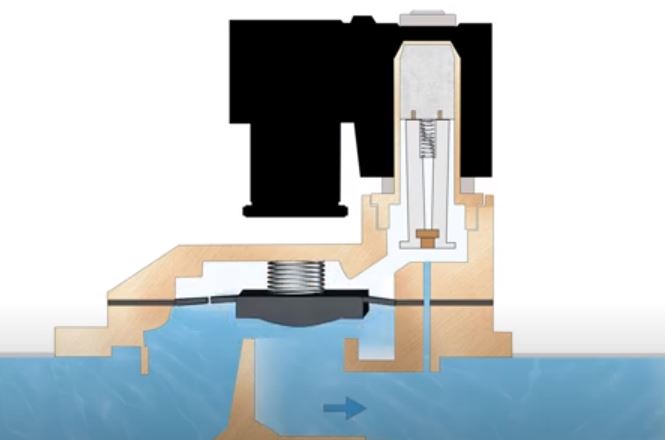

Pilot operated valves use a smaller control valve (pilot valve) to actuate a larger valve (main valve), allowing for the control of higher pressures with a smaller input force.

Pilot-operated valves are commonly used in various industrial applications where precise control of fluid flow is required. They are suitable for applications where the fluid pressure is relatively high, and the force required to operate the main valve is beyond what a direct-acting valve can handle efficiently.

These valves are often employed in processes where maintaining accurate control is crucial, such as in chemical plants, refineries, and other manufacturing facilities.

Conclusion

In conclusion, the proper selection and application of valves are paramount in ensuring the efficient and reliable operation of pneumatic systems. Understanding the different types of pneumatic valves and their specific functions enable engineers and technicians to design and maintain pneumatic systems that meet the diverse needs of various industries.

As technology advances, new valve designs and innovations continue to enhance the capabilities of pneumatic systems, contributing to increased precision, reliability, and efficiency in industrial processes.

1 thought on “Mastering different types of Pneumatic valves”

Comments are closed.