The Bowden cable is a deceptively simple technology that has been in use for over a century. It consists of a flexible inner cable that is surrounded by a sheath, with the two components working together to transmit force between two points. This basic design has proven to be incredibly versatile and has found application in a wide range of industries, from bicycles to automobiles to aerospace.

In this article, we will explore the different parts of a Bowden cable, its applications, and the advantages and disadvantages it offers compared to other transmission methods. By the end of this article, you will have a clear understanding of how the Bowden cable works and the many ways it is used to ensure smooth mechanical operations in a variety of settings.

What is a Bowden Cable? Understanding the Basics of this Innovative Control System

A Bowden cable, also known as a flexible shaft or a push-pull cable, is a control system used to transmit mechanical force or motion from one point to another. It consists of a flexible inner wire that runs through a sheath or casing. When the inner wire is pulled or pushed, it moves within the casing, transmitting the force or motion to the other end of the cable.

The Bowden cable was invented in the late 19th century by Ernest Monnington Bowden, a British engineer and inventor. Bowden was inspired by the flexible cables used in bicycle brakes and derailleurs and developed a similar system for controlling the carburetor on his motorcycle.

The Bowden cable proved to be a great success, and it has since been used in a wide variety of applications, including automotive, aviation, industrial, medical, and consumer products.

Bowden cable parts

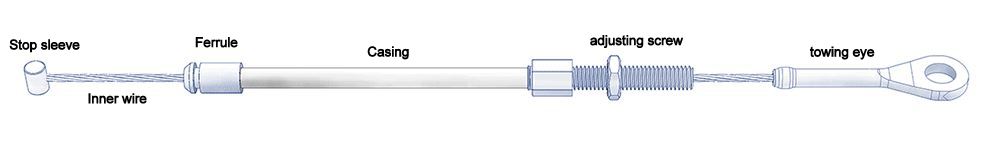

A Bowden cable consists of three main parts: the inner wire, the casing or sheath, the end fittings, and the Ferrules.

The Inner Wire: The inner wire is the flexible element of the Bowden cable. It is usually made of steel or other high-strength materials and can vary in diameter depending on the application. The wire can be solid or stranded and is typically coated with a lubricant to reduce friction and wear.

The Casing or Sheath: The casing or sheath is the outer covering of the Bowden cable. It is usually made of a flexible material such as nylon, PVC, or Teflon and is designed to protect the inner wire from dirt, moisture, and other contaminants. The casing can be reinforced with braided or spiral wires for added strength and durability.

The End Fittings: The end fittings are the components that connect the Bowden cable to the device it is controlling. They can be threaded or non-threaded and come in a variety of shapes and sizes to suit different applications. Common end fittings include clevises, eyelets, studs, and ball joints.

Ferrules: Ferrules are small metal or plastic components that are used to secure the end fittings to the Bowden cable. They are crimped or swaged onto the cable and provide a secure connection between the cable and the end fittings.

These are the main parts of a Bowden cable, but there may be additional components or variations in design depending on the specific application. It is important to choose high-quality components and to properly maintain and lubricate the cable to ensure its reliability and longevity.

What is the Bowden cable clamp?

A Bowden cable clamp is a device that is used to secure the outer casing or sheath of a Bowden cable to a surface or structure. The clamp is designed to hold the cable securely in place and prevent it from moving or slipping during operation.

Bowden cable clamps are typically made of metal or plastic and can be attached to a variety of surfaces, such as a frame, bracket, or panel. They are often used in applications where the cable needs to be routed through tight spaces or around corners, as they can help to keep the cable in place and prevent it from getting tangled or kinked.

There are several types of Bowden cable clamps available, including:

Screw-on clamps: These clamps feature a threaded screw that can be tightened to secure the cable in place. They are easy to install and can be adjusted for proper tension.

Adhesive clamps: These clamps use an adhesive backing to attach to a surface. They are quick and easy to install, but may not be as secure as screw-on clamps.

Snap-in clamps: These clamps snap onto the cable and can be easily installed or removed without tools. They are ideal for temporary applications or for cables that need to be adjusted frequently.

Bowden cable clamps are an important component of Bowden cable systems, as they help to ensure that the cable operates smoothly and reliably. They should be chosen based on the specific application and the size and type of cable being used. Proper installation and maintenance of the clamps are also important to ensure the longevity and effectiveness of the Bowden cable system.

Bowden cable housing

The Bowden cable housing, also known as the outer casing or sheath, is a protective cover that surrounds the inner wire of a Bowden cable. The housing is an important component of the cable system, as it provides several benefits including protection, flexibility, and resistance to kinking.

The housing of a Bowden cable is typically made of a durable and lightweight material such as nylon, PVC, or stainless steel. The material is chosen based on the specific application and the requirements of the system. For example, stainless steel housings are often used in harsh environments where corrosion resistance is important, while PVC housings may be used in applications where flexibility is a priority.

The Bowden cable housing provides several benefits including:

- Protection: The housing protects the inner wire from dirt, debris, and other environmental factors that can cause damage or wear. This helps to ensure the longevity and reliability of the cable system.

- Flexibility: The housing allows the cable to be routed through tight spaces and around corners, providing flexibility in the design of the system.

- Resistance to kinking: The housing helps to prevent the cable from kinking or bending sharply, which can cause damage or affect the performance of the system.

The housing of a Bowden cable can be reinforced with braided or spiral wires to increase its durability and resistance to kinking. The housing is typically attached to the end fittings of the cable using ferrules or other connectors.

Proper selection and installation of the Bowden cable housing are important to ensure the effectiveness and longevity of the cable system. The housing should be chosen based on the specific application and requirements of the system, and it should be properly maintained and lubricated to ensure the smooth operation of the cable.

Bowden cable control system

A Bowden cable control system is a mechanical control system that transmits force or motion from one point to another using a Bowden cable. The Bowden cable itself is a flexible control cable consisting of a tightly wound inner wire that moves within a protective outer casing or sheath.

The inner wire is usually made of steel or other high-strength materials, while the casing can be reinforced with braided or spiral wires to increase its durability.

In a Bowden cable control system, one end of the cable is attached to a control lever, pedal, or handle, while the other end is attached to a mechanism or device that performs a specific action, such as opening a valve, releasing a brake, or adjusting the position of a component.

When the control lever or handle is moved, it causes the inner wire of the Bowden cable to move, which in turn transmits the force or motion to the mechanism at the other end of the cable.

Bowden cable control systems are used in a wide variety of applications, including automotive, aerospace, marine, and medical devices. They are known for their flexibility, strength, and versatility, and they are often a preferred choice over other control systems due to their ability to be routed through tight spaces and their cost-effectiveness.

However, Bowden cable control systems can also have some disadvantages, such as friction, limited range of motion, and noisy operation, which should be considered when choosing a control system for a particular application.

Applications of Bowden Cables

Bowden cables are used in a wide variety of applications, including:

- Automotive: Bowden cables are used in car and truck control systems, such as brakes, throttles, and shifters.

- Aviation: Bowden cables are used in aircraft control systems, such as rudder and elevator controls.

- Industrial: Bowden cables are used in machinery and equipment control systems, such as conveyor belts, winches, and cranes.

- Medical: Bowden cables are used in medical devices, such as endoscopes and catheters.

- Consumer Products: Bowden cables are used in a variety of consumer products, such as bicycles, exercise equipment, and remote control toys.

Advantages of Bowden Cables

- Flexibility: One of the primary advantages of Bowden cables is their flexibility. Because the inner wire is flexible and can bend around corners, Bowden cables can be routed through tight spaces, making them ideal for applications where space is limited.

- High Strength: Bowden cables are also known for their strength. The inner wire is typically made of steel or other high-strength materials, and the casing can be reinforced with braided or spiral wires, giving the cable a high degree of durability.

- Versatility: Bowden cables can be used in a wide variety of applications, from automotive to aerospace to medical devices. They can be used to transmit force or motion in either direction and can be adjusted to suit the needs of the application.

- Cost-Effective: Bowden cables are also cost-effective compared to other control systems. They are relatively simple to manufacture, and the materials used are typically less expensive than those used in other types of control systems.

Disadvantages of Bowden Cables

- Friction: One of the primary disadvantages of Bowden cables is friction. Because the inner wire is moving within the casing, there is a potential for friction to occur, which can cause wear and tear on the cable and reduce its lifespan.

- Limited Range of Motion: Bowden cables are also limited in their range of motion. Because the cable is made up of a series of flexible elements, it can only transmit force or motion over a limited distance.

- Installation and Maintenance: Installing and maintaining Bowden cables can be more complex than other types of control systems. Because the cable consists of multiple parts, it can be challenging to install and maintain properly, and failure to do so can result in the cable malfunctioning or failing altogether.

- Noisy Operation: Bowden cables can also be noisy during operation. Because of the friction between the inner wire and the casing, the cable can produce a squeaking or grinding noise, which can be distracting or annoying in some applications.

Conclusion

In conclusion, Bowden cables are a versatile and reliable control system that has been used in a wide variety of applications for over a century. Whether it’s controlling the brakes on a car or the movement of a medical device, Bowden cables are an essential component of many mechanical