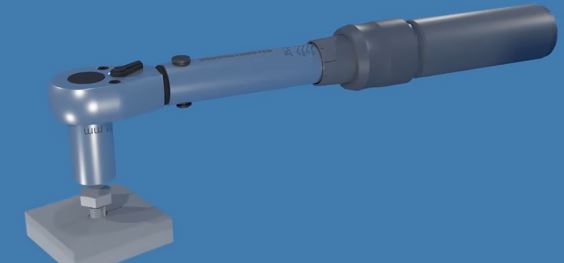

When it comes to tightening bolts, nuts, or fasteners to precise specifications, a torque wrench is an essential tool in any professional or DIY mechanic’s toolbox. In this article, we’ll dive deep into what a torque wrench is, why it’s crucial, how it works, and tips on choosing the right one for your needs.

What is a Torque Wrench?

A torque wrench is a tool that allows you to apply an exact amount of force to fasteners such as bolts or nuts. Unlike regular wrenches, torque wrenches ensure that you apply the right amount of force, preventing over tightening or under tightening, which could damage components or compromise safety.

Why is Torque Important?

Torque is the force that causes rotation. In mechanical systems, achieving the correct torque is critical to ensure that components are secured without being damaged. Too much torque can cause parts to deform or fail, while too little can result in parts loosening over time, leading to safety issues or performance problems.

Types of Torque Wrenches

There are numerous torque wrenches available on the market. Some of them are mentioned below with their unique features and uses:

Beam Torque Wrench

- Simple, easy to use and affordable

- A pointer near the handle that moves along a scale shows the torque being applied.

- Advantage: No need for calibration.

- Drawback: Less precise compared to other models and can be harder to read in low-light environments.

Click Torque Wrench

- Mostly used due to its unique features.

- When the preset torque is reached, a click sound will confirm it.

- Advantage: Highly accurate and easy to use.

- Drawback: Needs periodic calibration to maintain accuracy.

Digital Torque Wrench

- Features a digital display for real-time torque readings.

- Some models offer programmable settings and alarms.

- Advantage: Extremely accurate and convenient to use.

- Drawback: Can be expensive and requires battery power.

Split Beam Torque Wrench

- Similar to the click-type but more robust and requires less maintenance.

- Advantage: Does not need to be reset to zero after use, making it easier to maintain.

- Drawback: Less common and usually more expensive than the click type.

Hydraulic Torque Wrench

- Used for industrial applications where very high torque levels are required.

- Powered by hydraulic pressure, allowing it to deliver more torque than manual wrenches.

- Advantage: Capable of applying extreme torque.

- Drawback: Requires a hydraulic power source and is more complex to operate.

How to Use a Torque Wrench

Using a torque wrench properly is essential for achieving the correct amount of torque. Here are the basic steps:

- Select the Right Torque Wrench: Choose the appropriate type based on your needs. For automotive repairs, a click or beam torque wrench is usually sufficient.

- Set the Desired Torque: If using a click or digital torque wrench, adjust the torque setting to match the manufacturer’s specification for the fastener.

- Position the Wrench: Place the socket on the fastener and apply force slowly and steadily.

- Listen/Watch for Indicators: For click wrenches, stop applying force when you hear or feel the click. For beam wrenches, watch the indicator reach the desired torque level.

- Check Calibration: The reading of the torque wrench may change over time. That is why torque wrenches should be calibrated from an approved calibration center.

Torque Wrench Calibration

Torque wrenches are precision tools, and over time, they can drift out of calibration. Most manufacturers recommend calibrating torque wrenches at least once a year or after a set number of uses (typically 5,000). You can send your torque wrench to a professional calibration service or use an in-house calibration tool if available.

Choosing the Right Torque Wrench for Your Needs

Here are a few factors to consider when selecting a torque wrench:

- Accuracy Requirements: If precision is critical (e.g., engine assembly), opt for a digital or high-quality click wrench. For general tasks, a beam or split beam wrench might suffice.

- Torque Range: Choose a wrench that covers the range of torque values you’ll be working with. For automotive repairs, a range of 10–150 foot-pounds (ft-lbs) is typical.

- Durability and Maintenance: Look for tools made from durable materials like chrome vanadium or steel. Regular calibration is a must, so check the ease of maintaining the tool.

- Price: Beam wrenches are more affordable, but if you need more precision and ease of use, click or digital models are worth the investment.

Common Applications of Torque Wrenches

- Automotive Repairs: From lug nuts to engine bolts, a torque wrench ensures that parts are fastened securely.

- Bicycle Maintenance: Modern bikes, especially carbon fiber models, require specific torque levels to avoid damage.

- Aerospace and Industrial Use: In these fields, precision is non-negotiable, and torque wrenches are often used to tighten critical fasteners on machinery or aircraft.

- Home and DIY Projects: A torque wrench can be handy for assembling furniture or working on household appliances.

Tips for Extending the Life of Your Torque Wrench

- Store Properly: Store the wrench in a case when not in use to protect it from dirt, moisture, and damage.

- Release Tension: For click-type wrenches, always reset the torque setting to the lowest value after use.

- Avoid Drops: Dropping the wrench can knock it out of calibration or damage internal components.

- Clean Regularly: Wipe down your torque wrench after each use to prevent dirt from accumulating on moving parts.

Conclusion

A torque wrench is an indispensable tool for anyone working with fasteners that require precise tightening. Whether you’re a professional mechanic, a weekend DIYer, or a cyclist, having the right torque wrench ensures that your projects are completed safely and accurately. Understanding the different types of torque wrenches and how to maintain them will not only help you choose the right tool but will also ensure it lasts for years.