Aircraft are engineering marvels that demand the highest levels of safety, reliability, and performance. To achieve these standards, specialized fasteners play a crucial role in securing critical components and ensuring the structural integrity of an aircraft.

If you are in the aviation industry or want to become a knowledgeable aircraft maintenance engineer, you should have the knowledge of special fasteners used in the aircraft. This article explores the world of special fasteners used in aircraft, along with other commonly employed fasteners in aviation.

Special Fasteners Types

There are many types of special fasteners used in the aircraft as demanded by the location and safety and structural conditions. Here in this article we will try to learn most of them that are commonly used in the aircraft structure and equipment.

- Huck bolts

- Hi-lock fasteners

- CherryMax and CherryLock rivets

- Camloc fasteners

- Quarter-turn fasteners

- Dzus fasteners

- Self-locking nuts

Huck Bolts

Huck bolts, also known as structural blind bolts, are renowned for their exceptional strength. They are specifically designed for joining structural components in areas where high load-carrying capability is required.

What sets Huck bolts apart is their ability to be installed from one side, eliminating the need for access to the opposite side of the joint. This characteristic simplifies and expedites assembly, making them invaluable in aircraft manufacturing and maintenance.

Hi-Lok Fasteners

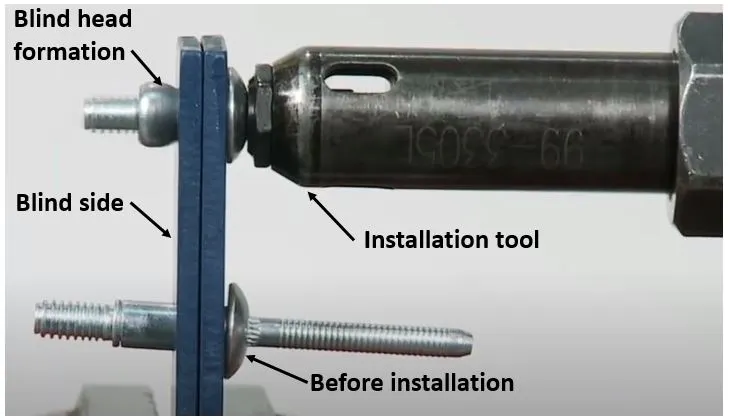

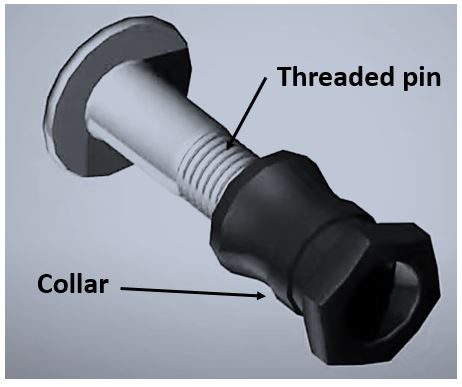

One of the most widely used special fasteners in aerospace applications is the Hi-Lok fastener. These high-strength, threaded fasteners consist of a collar and a threaded pin.

Hi-Lok fasteners excel in their ability to resist vibrations and fatigue, making them ideal for aircraft structures that experience dynamic loads. These fasteners are installed using a specialized installation tool, ensuring precise and secure attachment.

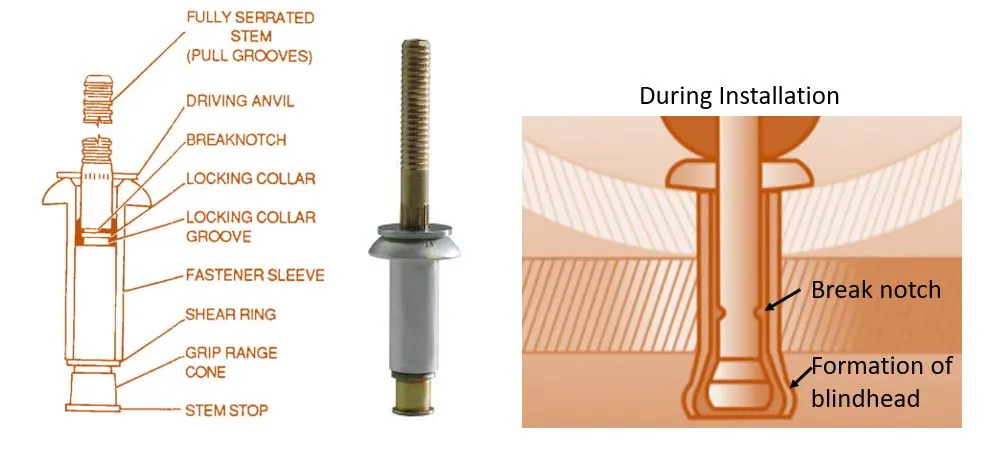

CherryMax/CherryLock Rivets

CherryMax and CherryLock rivets are widely utilized blind rivets in the aviation industry. These rivets offer high shear and tensile strength, making them ideal for applications where a sealed joint is necessary.

They find extensive use in aircraft construction, particularly in areas like fuel tanks and pressurized cabins. The secure and reliable fastening provided by CherryMax and CherryLock rivets ensures the integrity of critical components, enhancing safety in flight.

Camloc Fasteners

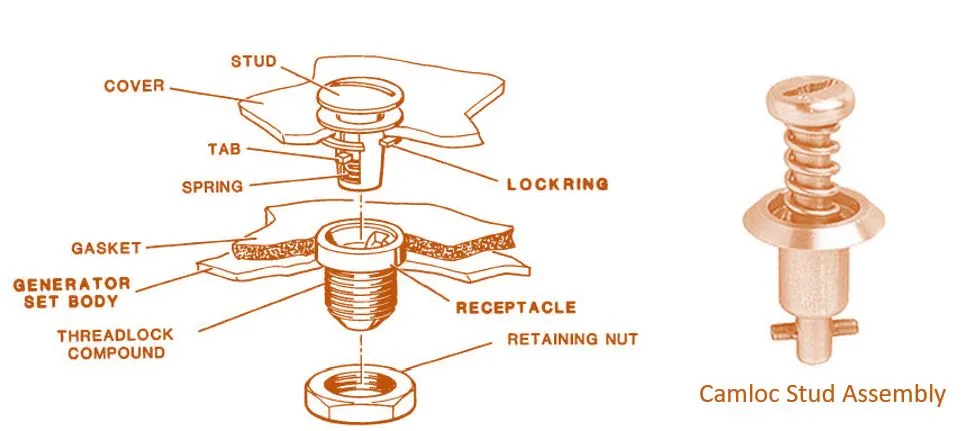

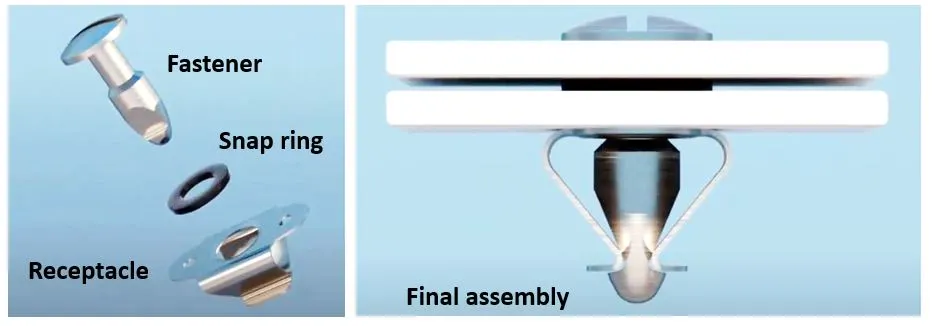

Camloc fasteners provide a quick-release solution for securing panels, cowls, and other removable components in aircraft. These fasteners consist of a stud and a receptacle that engage and lock securely when joined.

They can be easily released by applying a specific amount of force, facilitating swift access to the underlying components. Camloc fasteners are widely employed in aircraft maintenance, where rapid removal and reinstallation of panels are necessary.

Quarter-Turn Fasteners

Quarter-turn fasteners are simple yet effective mechanisms used to secure various aircraft components. With a straightforward design, they can be swiftly installed or removed by rotating them a quarter turn. Dzus fastener is also known as quarter-turn fastener.

These fasteners find widespread use in securing panels, fairings, and other removable parts. Their ease of use and reliability make them a popular choice in aviation applications.

Dzus Fasteners

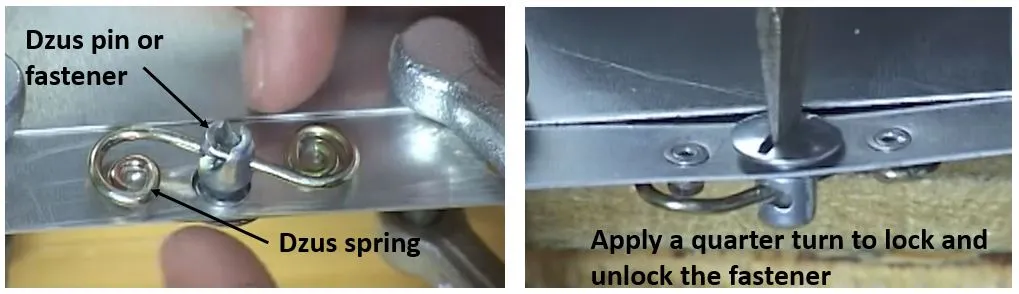

Dzus fasteners, also known as Dzus clips or quick-turn fasteners, are widely used in aircraft for securing panels and access doors. The fastener has a special channel on the pin and a spring called Dzus spring.

The spring will be underneath the panel or sheet and the fastener (pin) will catch the wire of the spring by the channel of the fastener after twisting it. The spring-loaded feature mechanism allows for rapid installation and removal with a quarter turn.

Dzus fasteners enable efficient access to critical components while ensuring a secure and reliable attachment, thereby streamlining maintenance procedures.

Self-locking Nuts

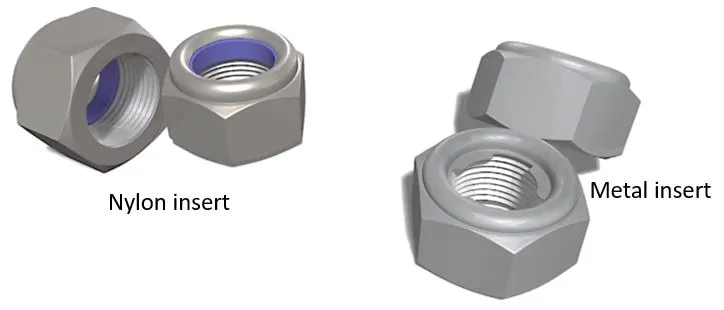

In applications where vibration poses a risk of loosening regular nuts, self-locking nuts come into play. These nuts incorporate a locking feature, such as a nylon insert or a metal deformation, that prevents them from loosening under normal operating conditions.

Self-locking nuts are crucial in areas where component integrity must be maintained, minimizing the chances of fastener failure.

Conclusion

Special fasteners play a vital role in maintaining the safety, reliability, and structural integrity of aircraft. From Hi-Lok fasteners and Huck bolts to CherryMax rivets and Camloc fasteners, each type serves a specific purpose, addressing the unique demands of aviation applications.

The careful selection and implementation of these specialized fasteners ensure that critical components remain securely fastened, contributing to the overall safety and performance of aircraft in the sky.