Fasteners are mechanical devices used to join, secure, or hold objects together. It is a broad term that encompasses various types of mechanical components designed to hold things in place. Fasteners are widely used in construction, manufacturing, automotive, aerospace, and many other industries. They create a non-permanent or semi-permanent joint without damaging the workpiece or base materials.

Different types of fasteners

Nuts

Nuts are threaded fasteners with a hole in the center. They are used in combination with bolts or screws to create a secure joint. Generally two types of nut are found- self-locking and non-self locking nuts.

A self-locking nut is a type of fastener that incorporates a design feature or a separate component to prevent the nut from loosening due to vibration, or other external forces.

On the other hand, a non-self-locking nut is a standard type of nut that does not have any built-in features to prevent it from loosening on its own. To prevent it from loosening an extra fastener is used such as wire lock, cotter pin, lock nut etc.

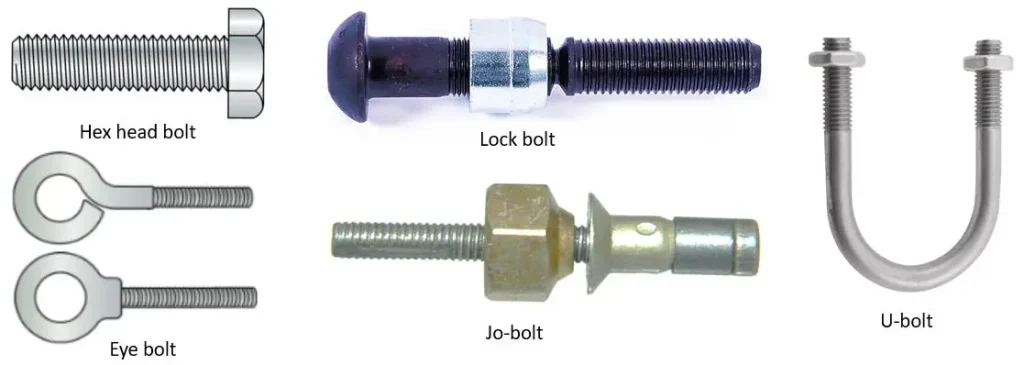

Bolts

A bolt is a type of threaded fastener used to join two or more components together by creating a strong and secure connection. It consists of a cylindrical shaft with a helical ridge, known as threads, along its length. The bolt is designed to be paired with a nut, which has matching threads, to form a bolted joint.

Bolts come in various sizes, lengths, and materials, depending on the specific application and the requirements of the joint. They can be made of steel, stainless steel, brass, or other alloys, each offering different properties such as strength, corrosion resistance, and temperature resistance.

Screws

Screws have a helical ridge (thread) around their shaft, and they are used to create a fixed joint by being driven into a material like wood, metal, or plastic.

Screws come in various shapes and sizes, each designed for specific applications. Some common types of screws include- wood screw, machine screw, self-tapping screw, sheet metal screw, concrete screw etc.

Rivets

Rivets are permanent fasteners used to join materials together by deforming the end of the rivet after it’s inserted through the materials. Unlike screws and bolts, rivets do not have threads. Instead, they have a plain rod known as shank and a preformed head at one end.

Rivets work by deforming the tail end to create a bulged head, which locks the materials together, providing a strong and secure connection. There are different types of rivets found in the manufacturing process such as- solid rivets, blind rivets (pop rivets), Tubular rivets, drive rivets etc.

Washers

It is a circular object made from thin sheets containing a hole in the center to receive a bolt. They are used to distribute the load of a fastener and prevent damage to the material being fastened.

Different types of washers include-flat washers, spring washers(Belleville Washers), lock washers, Toothed (Serrated) Washers, Toothed (Serrated) Washers etc.

Nails

Nails are slender, pointed metal fasteners used to join materials together by penetrating and securing them in place.

They are one of the oldest and simplest types of fasteners and have been used for thousands of years in various construction, woodworking, and crafting applications. Nails come in different sizes and styles to suit different materials and purposes.

Clips and Clamps

These fasteners are used to hold objects together or secure them to a surface without the need for screws or bolts. Clips and clamps are essential tools in various industries, including woodworking, construction, manufacturing, automotive, and household applications.

They provide a secure and temporary or permanent hold on objects, making them invaluable for organizing, assembling, and repairing various items. The choice of clip or clamp depends on the specific task and the materials being worked with.

Clips are different types such as- paper clips, binder clips , retainer clips etc. whereas clamps are- wood making clamps, spring clamps, hose clamps, pipe clamps, cable clamps etc.

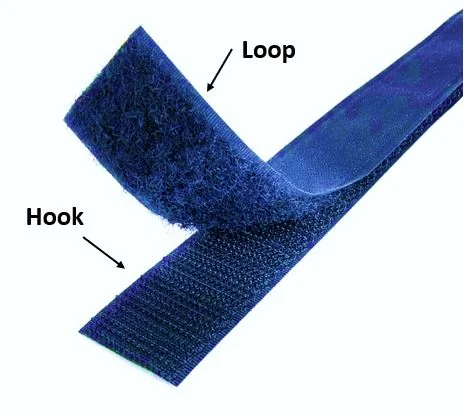

Velcro

Velcro is a hook-and-loop fastener system, often used in fabric and clothing applications.The key advantages of Velcro include its ease of use, adjustable fastening, reusability, and resistance to wear and tear.

Its ability to provide a strong yet temporary bond makes it a valuable fastening solution in many different fields. Velcro has become an integral part of modern life, providing convenience and practicality in numerous everyday applications.

Fasteners come in various shapes, sizes, and materials, depending on the specific application and the load requirements. They play a crucial role in building and assembling structures, machines, and products, providing the necessary strength and stability to keep components together.

Power fasteners

The term “power fastener” generally refers to a type of fastening system that utilizes power tools or equipment to drive fasteners into materials quickly and efficiently. These power fasteners are designed to expedite the installation process, especially in large-scale projects or applications where a significant number of fasteners need to be driven into materials rapidly.

There are several types of power fasteners commonly used in construction, manufacturing, and other industries. Some examples include:

Power Nailer

A power nailer, also known as a nail gun, is a tool that uses compressed air, electricity, or gas to drive nails into various materials, such as wood, metal, or concrete. They are used in wood works and building construction works.

Power Screwdriver

A power screwdriver is an electric or battery-powered tool used to drive screws into materials quickly and with less manual effort. It is commonly used for assembling furniture, installing drywall, and other tasks that involve driving multiple screws.

Powder-Actuated Fasteners

Powder-actuated fasteners are used in construction and industrial applications to fasten materials to concrete, steel, or other hard surfaces. They use a controlled explosion or a powder charge to drive nails or pins into the materials.

Power Riveter

A power riveter is a tool that uses hydraulic or pneumatic pressure to fasten rivets into materials, providing a quick and efficient way to join metal components.

Power Stud Welder

A power stud welder is used in welding applications to attach studs to metal surfaces quickly and securely using a high-energy arc.

Power Anchoring System

Power anchoring systems use specialized tools to install anchors into concrete or masonry materials, providing a strong and reliable hold for various applications.

These power fastening tools and systems are invaluable in industries where speed, efficiency, and precision are crucial. They help reduce manual labor, increase productivity, and ensure consistent and reliable fastener installations. However, it’s essential to use these tools with proper safety precautions and adhere to the manufacturer’s guidelines for the specific type of fastener and material being used.

3 thoughts on “Fastener Knowledge for Becoming An Expert Maintenance Engineer!”

Comments are closed.