A Dzus fastener, also known as a quarter-turn fastener, is a type of quick-release fastener commonly used in various industries, including aviation, aerospace, automotive, and other applications where rapid access and secure closure are required.

The name “Dzus” comes from the company that originally popularized and patented this type of fastener, but the term is often used generically to refer to similar fasteners made by various manufacturers.

Dzus fastener construction

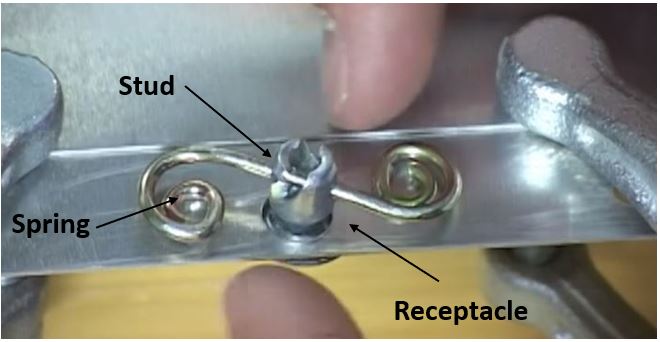

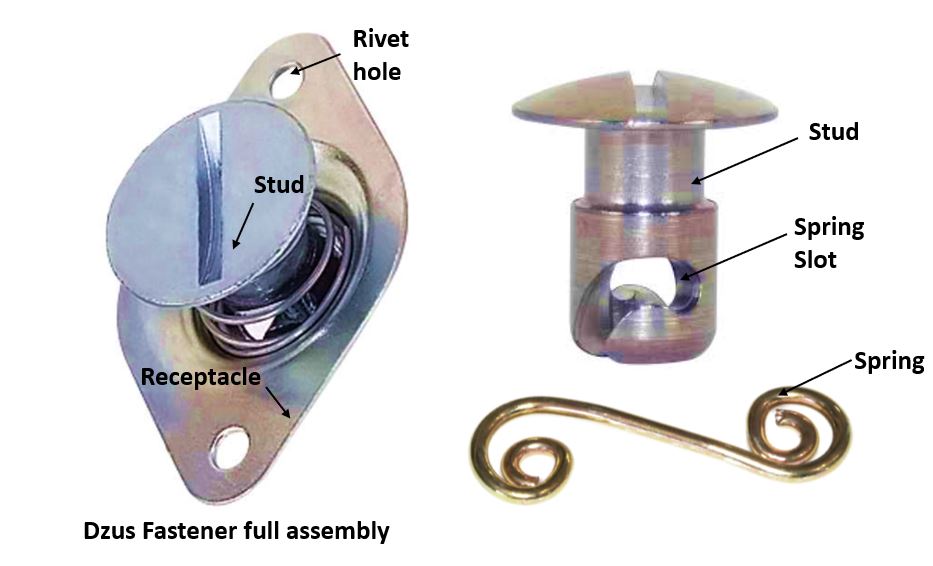

The Dzus fastener consists of two main components:

Receptacle: The receptacle is a small metal or plastic part that is attached to one surface or panel. It has a hole or receptacle where the fastener stud will fit.

Stud: The stud is a threaded or non-threaded pin that is attached to the opposing surface or panel. It is inserted into the receptacle and then turned a quarter-turn to lock it securely in place. The stud typically has a small head or handle for easy turning.

Dzus Fastener operation and Applications

To operate a Dzus fastener, you simply align the stud with the receptacle and insert it. Then, you give the stud a quarter-turn, and it locks firmly into place, securing the two surfaces together.

To release the fastener, you turn the stud in the opposite direction a quarter-turn, and it will pop out of the receptacle, allowing for quick access to the interior of the assembly.

Dzus fasteners are widely used in the aerospace industry for securing aircraft panels, access doors, fairings, and other components that need to be frequently removed and reinstalled for maintenance or inspection.

They are preferred in these applications because they offer a quick and secure method of attachment without the need for tools or additional hardware.

In recent years, variations of the Dzus fastener have been developed by different manufacturers, and the term “Dzus fastener” has become somewhat of a generic term for any similar type of quarter-turn fastening system, regardless of the specific brand or design.

Dzus fastener installation

Installing Dzus fasteners is a straightforward process, and it requires minimal tools and hardware. Here are the general steps to install Dzus fasteners:

Materials needed:

- Dzus fasteners (studs and receptacles)

- Panels or surfaces to be fastened

- Rivets or screws (if required for mounting the receptacles)

- Rivet gun or screwdriver (if using rivets or screws)

- Pliers (for some Dzus fastener types)

Step-by-step installation process:

Position the Receptacles:

Determine the locations on the surfaces or panels where you want to install the Dzus receptacles. Place the receptacles with the threaded hole facing outward, aligning them to ensure a proper fit when the studs are inserted.

Mark the Mounting Holes:

Once the receptacle positions are determined, use a pen or marker to mark the locations for the mounting holes. These holes will be used to attach the receptacles to the surfaces.

Attach the Receptacles:

If you’re using rivets, drill pilot holes at the marked locations. Then, insert the rivets through the holes in the receptacles and secure them to the surfaces using a rivet gun. If you’re using screws, drill appropriately sized pilot holes and attach the receptacles using the screws and a screwdriver.

Position the Studs:

Determine the corresponding positions on the opposing surfaces or panels where the studs will be installed. The studs should align with the receptacles for a proper fit.

Insert the Studs:

For some Dzus fasteners, you may need to use pliers to grip and turn the studs. For others, you can turn them by hand. Align the studs with the receptacles and insert them into the receptacle holes. Give the stud a quarter-turn clockwise to lock it into place. You should feel or hear a click when the stud is securely fastened.

Test and Adjust:

After installing all the Dzus fasteners, test the connections by gently pulling or pushing the panels to ensure they are securely locked in place. If any fasteners feel loose, double-check the alignment and make any necessary adjustments.

It’s important to follow any specific instructions provided by the manufacturer of the Dzus fasteners you are using. Additionally, some Dzus fasteners may have different installation methods or additional steps, so always refer to the product documentation for the most accurate guidance.