Cleco fasteners (also known as Clecos) are temporary fasteners used primarily in the aerospace and aviation industries during the assembly and fabrication of aircraft. They are essential tools for holding multiple sheets of metal together in precise alignment before permanent fastening, such as riveting or welding, takes place.

Key features of Cleco fasteners

- Design

Cleco fasteners consist of two main parts: a cylindrical body with spring-loaded plunger and a separate copper or steel pin with a wedge-shaped head.

- Temporary Holding

Clecos are used to temporarily hold sheets of metal or other materials together, maintaining alignment and preventing movement during the assembly process.

- Easy Installation

To use Cleco fasteners, you insert the pin through the aligned holes in the materials, and then insert the fastener body into the pin’s end. The spring-loaded plunger holds the fastener securely in place.

- Removal

When the permanent fastening process is ready (e.g., riveting or welding), you can easily remove the Cleco fasteners by squeezing the plunger and pulling the fastener body out of the pin.

- Multiple Sizes

Cleco fasteners come in various sizes and lengths to accommodate different material thicknesses and applications.

Construction of the Cleco fasteners

Cleco fasteners, also known simply as Clecos, are temporary fasteners commonly used in the aerospace and aviation industries during the assembly and fabrication of aircraft and sheet metal structures.

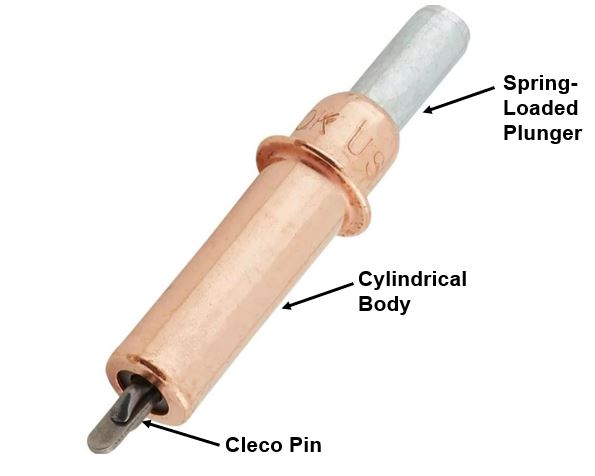

They consist of two main components: a cylindrical body with a spring-loaded plunger and a separate copper or steel pin with a wedge-shaped head. A Cleco fastener has the following constructions:

Cylindrical Body

The main part of the Cleco fastener is the cylindrical body.The body has a hollow tube-like shape, open at one end and closed at the other. The body is normally made of Aluminum or steel.

Spring-Loaded Plunger

Inside the cylindrical body, there is a spring-loaded plunger mechanism. The plunger is responsible for securing the fastener in place when inserted into the Cleco pin.

Cleco Pin

The Cleco pin is a separate component that accompanies the cylindrical body. It is a solid metal pin with a wedge-shaped head. The wedge shape allows for easy insertion of the Cleco pin into aligned holes in two or more pieces of material that need to be temporarily held together.

Knurled Grip

The end of the Cleco pin opposite the wedge-shaped head often has a knurled grip, providing a textured surface for easy handling and insertion into the fastener body.

The construction of Cleco fasteners is relatively simple, but it is their design that makes them effective for their intended purpose.

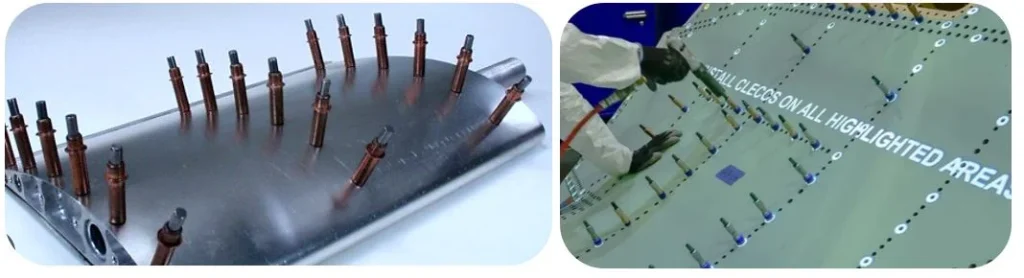

When assembling or aligning sheets of metal or other materials, Cleco fasteners are inserted through aligned holes in the materials, and the spring-loaded plunger in the cylindrical body holds the fastener securely in place.

This allows the materials to be temporarily held together with precision, maintaining alignment and preventing movement during the assembly process.

Once the permanent fastening process, such as riveting or welding, is ready to proceed, Cleco fasteners can be easily removed by squeezing the plunger and pulling the fastener body out of the pin.

Cleco fasteners are invaluable tools in industries where accurate alignment and temporary holding of materials are crucial for creating strong and reliable structures.

Their simple yet effective construction makes them a staple in aircraft assembly, metal fabrication, and other construction applications.

Applications of Cleco Fasteners

Cleco fasteners, also known as Clecos, are primarily used in the aerospace and aviation industries during the assembly and fabrication of aircraft. However, they can also find applications in various metalworking and sheet metal projects. Here are some specific use cases for Cleco fasteners:

- Aircraft Assembly: Cleco fasteners are widely used in aircraft assembly to temporarily hold metal sheets, panels, and components together during the construction process. They ensure precise alignment before permanent fastening methods, such as riveting or welding, are applied.

- Sheet Metal Work: In metal fabrication and sheet metal work, Clecos are used to temporarily hold sheets of metal together while layout work is done or during the fitting process. They help maintain alignment and prevent shifting during cutting, drilling, and other metalworking operations.

- Metal Structures: Cleco fasteners are employed in various metal structure assembly tasks, such as building framework, trusses, and other metal components where temporary holding and alignment are essential.

- DIY Projects: Clecos can be valuable tools in DIY projects involving metal fabrication or sheet metal work. They assist in holding pieces together during construction or repair tasks.

- Prototype Development: In the prototyping and design phases of new aircraft or metal structures, Cleco fasteners allow engineers and manufacturers to assess and refine the assembly before finalizing permanent fastening methods.

- Temporary Fixture: Clecos can serve as temporary fixtures for holding jigs, templates, or other pieces in place while aligning or assembling various parts.

The key benefit of Cleco fasteners is their ability to provide accurate alignment and temporary holding during the assembly process.

They help prevent materials from shifting or misaligning, ensuring that the final product meets the necessary tolerances and specifications.

Once the permanent fastening is ready to proceed, Clecos are easily removed, leaving clean and precise holes for the final fasteners.

While Cleco fasteners are most prevalent in aviation and metalworking industries, their versatility and practicality make them useful tools in various other construction and fabrication tasks where precise alignment and temporary holding are required.

How to use Cleco fasteners?

Using Cleco fasteners is a straightforward process that involves temporarily holding metal sheets or components together during the assembly or fabrication process.

Clecos are commonly used in the aerospace and aviation industries, as well as metalworking and sheet metal projects. Here’s a step-by-step guide on how to use Cleco fasteners:

Materials needed

- Cleco fasteners (cylindrical bodies with spring-loaded plungers and Cleco pins)

- Drill with appropriate drill bit (optional, for creating holes)

- Metal sheets or components to be joined

- Pliers (optional, for gripping the Cleco pins)

Step-by-step process

- Preparation: Ensure that the metal sheets or components you want to join are correctly aligned and positioned for assembly. If necessary, use a ruler, straightedge, or template to guide the alignment.

- Drilling Holes (if required): If the metal sheets do not already have holes for Cleco fasteners, use a drill with the appropriate drill bit to create holes through the aligned sections. The hole size should match the diameter of the Cleco pin.

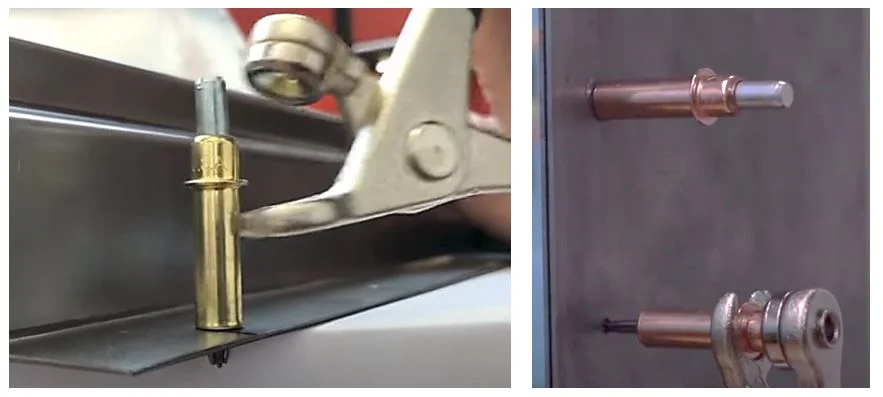

- Inserting Cleco Pins: Take a Cleco pin and insert the wedge-shaped head into one of the aligned holes. If the pin is a bit difficult to insert, you can use pliers to grip the knurled grip at the opposite end for better leverage.

- Inserting Cleco Fasteners: Once the Cleco pin is in place, take a cylindrical Cleco fastener body with the spring-loaded plunger and insert it into the open end of the Cleco pin. Push the fastener body until the plunger engages and holds the pin securely in place.

- Repeating the Process: Depending on the size and complexity of the assembly, you may need to repeat the process for multiple Cleco fasteners to ensure the entire section is temporarily held together.

- Verification: Check the alignment and fit of the joined pieces to ensure they are precisely aligned before proceeding with permanent fastening, such as riveting or welding.

- Removal: When you are ready to permanently fasten the assembly, use pliers to squeeze and depress the spring-loaded plunger on each Cleco fastener. This will release the fastener body from the Cleco pin. Then, pull the fastener body out of the hole, leaving the hole clean and ready for the final fastener.

- Permanent Fastening: With the Clecos removed, you can proceed with the final permanent fastening process, such as riveting, welding, or bolting, to secure the assembly permanently.

Cleco fasteners are valuable tools for holding metal sheets and components in precise alignment during assembly, making them a critical part of aircraft construction and various metalworking projects.

So, if you want to become a skilled aircraft maintenance engineer or other engineering personnel or a good workshop expert, your should have above mentioned knowledges about this very simple handy fasteners.