Have you ever wondered how passengers and crew stay safe and comfortable during flights that soar miles above the earth’s surface? At such high altitudes, the air is too thin to breathe, and that’s where aircraft oxygen systems come into play.

These systems are the unsung heroes of aviation, ensuring everyone on board can breathe easy, even when emergencies strike. In this article, we’ll explore how these systems work, their components, and why they’re so vital to flight safety.

Importance of Oxygen Systems

At altitudes above 10,000 feet, the partial pressure of oxygen decreases significantly, leading to hypoxia—a condition where the body lacks adequate oxygen. Modern aircraft are designed to maintain a pressurized cabin, but oxygen systems serve as a vital backup in case of cabin depressurization or for certain operational needs.

Types of aircraft Oxygen Systems

Aircraft oxygen systems can be broadly categorized into two types: gaseous oxygen systems and chemical oxygen systems.

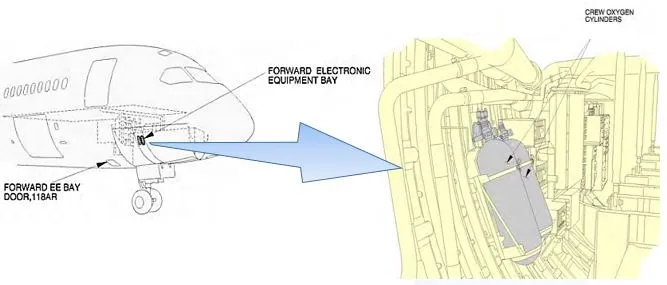

1. Gaseous Oxygen Systems

These systems use pressurized oxygen stored in cylinders. They are further divided into:

- Continuous Flow Systems:

- Common in general aviation and for passengers.

- Oxygen flows continuously to the user, regardless of their breathing pattern.

- Demand and Pressure-Demand Systems:

- Used primarily by pilots and crew.

- Supply oxygen only when the user inhales, conserving oxygen.

- Pressure-demand systems provide oxygen under slight positive pressure, suitable for very high altitudes.

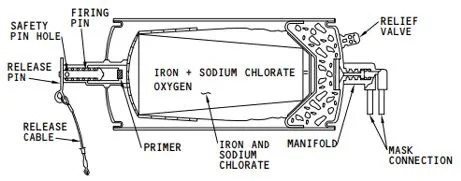

2. Chemical Oxygen Systems

These systems generate oxygen through a chemical reaction. Due to their compact design and minimal weight, they are well-suited for use in emergencies. The most common type is the oxygen generator found in passenger masks. Upon activation, a chemical reaction—typically involving sodium chlorate—produces oxygen for a limited duration.

Components of aircraft Oxygen Systems

The key components of an aircraft oxygen system include:

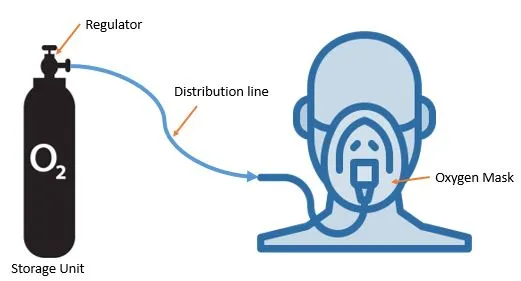

- Oxygen Storage Units:

- Cylinders or chemical canisters that store or generate oxygen.

- Must be inspected and maintained regularly to prevent leaks.

- Distribution System:

- Tubes and valves that deliver oxygen from the storage unit to the user.

- Regulators:

- Regulate the oxygen flow and pressure to ensure it is delivered safely.

- These can operate manually or automatically, based on the system’s configuration.

- Masks:

- Provide a secure interface between the user and the oxygen system.

- Types include:

- Passenger masks: Typically simple and drop automatically during depressurization.

- Crew masks: Equipped with microphones for communication and designed for prolonged use.

- Monitoring and Control Systems:

- Instruments to monitor oxygen levels, pressures, and flow rates.

Portable Aircraft Oxygen Systems

Portable oxygen systems are lightweight and versatile devices used in various aviation scenarios. They are particularly valuable for:

- Medical Emergencies:

- These systems can provide oxygen to passengers or crew experiencing medical distress.

- They are easy to transport and can be used throughout the cabin or cockpit.

- Supplementary Oxygen Needs:

- Portable systems are often used by crew or passengers during non-emergency situations, such as long flights at high altitudes in unpressurized aircraft.

Operation and Usage

In an emergency, such as cabin depressurization, oxygen masks automatically deploy in passenger compartments. Crew members use quick-don masks to ensure they can operate the aircraft safely. Pilots also rely on oxygen systems during flights above 10,000 feet in unpressurized aircraft or in case of pressurization system failures.

Aircraft Oxygen System Maintenance and Inspection

Maintaining an aircraft’s oxygen system is paramount for safety. Key aspects include:

- Regular Inspections:

- Cylinders must be checked for pressure levels and leaks.

- Regulators and masks should be inspected for functionality and cleanliness.

- Refilling and Replacement:

- Gaseous oxygen cylinders require periodic refilling.

- Chemical generators must be replaced after activation or expiry.

- Leak Testing:

- Ensures the integrity of the distribution system.

- Follow the maintenance manual to do the leak test.

- Training and Documentation:

- Maintenance personnel must be trained in handling oxygen systems due to their high-pressure nature and potential hazards.

Servicing Aircraft Oxygen Systems

Proper servicing of an aircraft oxygen system is essential to ensure its reliability and functionality. Key servicing tasks include:

- Cylinder Servicing:

- Cylinders should be periodically hydrostatically tested to ensure they can withstand high-pressure environments.

- Inspect for physical damage such as dents or corrosion.

- Refilling Procedures:

- Use only approved oxygen refilling equipment to prevent contamination.

- Ensure the filling environment is clean and free from oil or grease.

- Mask Maintenance:

- Clean masks using non-abrasive materials and approved cleaning agents.

- Inspect for cracks, tears, or loose fittings that may compromise their functionality.

- System Calibration:

- Test the regulators and monitoring systems to ensure accurate oxygen flow and pressure.

- Verify the functionality of automatic deployment systems.

- Documentation:

- Record all maintenance activities, including inspections, refilling, and component replacements, to comply with regulatory requirements.

Safety Precautions

Handling oxygen systems requires adherence to strict safety protocols:

- Avoid oil or grease contamination, as oxygen can react explosively with these substances.

- Ensure proper storage and transportation of oxygen cylinders.

- Follow manufacturer’s guidelines for servicing and replacement.

Conclusion

Aircraft oxygen systems are indispensable for ensuring safety at high altitudes. Whether through gaseous storage, chemical generation, or portable systems, these technologies provide a reliable supply of oxygen during emergencies or specific operational needs. Proper maintenance and understanding of these systems are essential for the safety of passengers and crew alike.