Hydraulic accumulators are essential components in hydraulic systems. They serve various purposes, from storing energy to maintaining pressure, and ensuring smooth system operation. Whether you’re a hydraulic technician, a student, or just someone interested in fluid power systems, this article will provide a comprehensive overview of hydraulic accumulators, types, symptoms of failure and maintenance instructions.

What is a Hydraulic Accumulator?

A hydraulic accumulator is a device that stores energy in the form of pressurized fluid. It helps regulate pressure in hydraulic systems, absorbs shocks, and ensures consistent performance. The stored energy can be released when there is a drop in system pressure or a sudden demand for power, thus maintaining system efficiency and protecting components.

How Hydraulic Accumulators Work

The basic principle behind an accumulator is simple. It consists of a chamber filled with hydraulic fluid and a precharged gas, usually nitrogen. When the hydraulic system operates, fluid enters the accumulator, compressing the gas and storing energy. When the system demands fluid or pressure drops, the gas expands, forcing the fluid back into the circuit.

Key Functions of Hydraulic Accumulators

- Energy Storage: Accumulators store energy that can be used during peak demand times, such as when a hydraulic pump is running at lower speeds or is off.

- Pressure Maintenance: They maintain pressure in hydraulic systems by releasing stored fluid when pressure falls below a set point, ensuring consistent operation.

- Shock Absorption: Hydraulic accumulators act as a buffer against pressure surges or shocks in the system, preventing damage to sensitive components.

- Flow Pulsation Dampening: In systems with pumps producing pulsating flow, accumulators help smooth out these fluctuations, providing a steady flow of fluid.

- Leak Compensation: If there is a small leak in the system, an accumulator can compensate for fluid loss, preventing pressure drop.

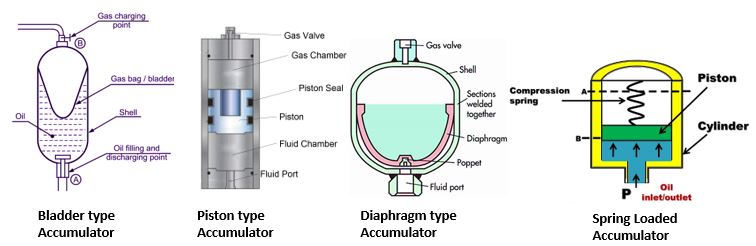

Types of Hydraulic Accumulators

There are several types of hydraulic accumulators, each designed for specific applications. The most common types include:

- Bladder Accumulators:

- A bladder accumulator uses a rubber bladder inside a steel shell. The bladder is precharged with nitrogen, and the hydraulic fluid compresses the bladder as the system’s pressure rises. These are compact and highly effective for absorbing shocks and storing energy.

- Piston Accumulators:

- Piston accumulators use a piston to separate the hydraulic fluid and the gas in the chamber. These are suitable for higher pressure and larger systems and are typically used in industrial applications. The piston allows for greater fluid volume storage compared to bladder accumulators.

- Diaphragm Accumulators:

- Similar to bladder accumulators but using a diaphragm to separate the fluid and gas. These accumulators are often used in systems that require lower volumes of stored fluid and moderate pressure ranges.

- Spring-Loaded Accumulators:

- In these, a spring is used to apply force on the hydraulic fluid, which can be an alternative to gas as a means of pressure storage. These are less common but still found in some applications requiring simple, direct energy storage.

Applications of Hydraulic Accumulators

Hydraulic accumulators are used across various industries, including:

- Aerospace: In aircraft hydraulic systems to maintain pressure during engine or pump failures.

- Automotive: For energy storage and maintaining consistent braking pressure in hydraulic brake systems.

- Industrial: In manufacturing equipment to provide backup pressure and energy storage.

- Marine: In hydraulic winches or steering systems where shock absorption and pressure regulation are critical.

- Offshore Oil and Gas: For controlling blowout preventers and other critical equipment where pressure maintenance is vital.

Hydraulic Accumulator Failure Symptoms

Symptoms of hydraulic accumulator failure can include:

- Loss of Pressure: A noticeable drop in system pressure, which may lead to performance issues in hydraulic machinery.

- Increased Noise: Unusual sounds such as banging or clattering during operation, indicating gas or fluid issues within the accumulator.

- Fluid Leakage: Visible leaks around the accumulator seals or connections.

- Poor Performance: Inconsistent or jerky movements of hydraulic equipment due to insufficient accumulator support.

- Frequent Cycling: An unusually high number of cycles in the hydraulic system, indicating that the accumulator is not providing adequate pressure.

- Overheating: The hydraulic fluid may become excessively hot due to improper functioning of the accumulator.

If any of these symptoms are observed, it is important to conduct further investigation or seek professional maintenance to prevent damage to the hydraulic system.

Hydraulic Accumulator Maintenance

Maintaining hydraulic accumulators is crucial to ensure that they function properly and have a long service life. Regular checks should include:

- Pressure Testing: Ensure the accumulator has the correct precharge pressure, which is essential for optimal performance.

- Inspection of Seals and Bladders: Over time, seals and bladders may degrade, which can lead to leaks or loss of gas pressure.

- Cleaning: Remove any contaminants from the hydraulic fluid that could affect the accumulator’s performance.

- Monitoring System Performance: Regularly monitor system performance to detect any pressure drops or inconsistencies.

Conclusion

Hydraulic accumulators are vital to the proper functioning of hydraulic systems, providing pressure maintenance, energy storage, shock absorption, and other benefits. Understanding the different types of accumulators and how they work is crucial for anyone working in the field of hydraulics.

Maintaining and selecting the right hydraulic accumulator for your system can help ensure optimal performance, longer equipment lifespan, and reduced downtime. Whether you are involved in industrial, aerospace, or automotive applications, knowing the role of hydraulic accumulators can significantly enhance your system’s efficiency and reliability.