Have you ever found yourself at 35,000 feet, gazing out of an airplane window and wondering about the mysteries unfolding beneath the pristine wings? Amidst the awe-inspiring journey through the boundless sky, questions linger—where does the waste of hundreds of passengers vanish, and from what ethereal source do the gallons of water appear? Brace yourselves for an exploration into the unseen realms of aviation, where the answers to these intriguing inquiries reside.

Aircraft Potable Water System

The potable water system in an aircraft refers to the system responsible for storing, distributing, and providing drinkable water for various uses on board. Potable water, in this context, means water that is safe and suitable for human consumption. The potable water system is a critical component to ensure the well-being and comfort of passengers and crew during a flight.

Key components of an aircraft potable water system include

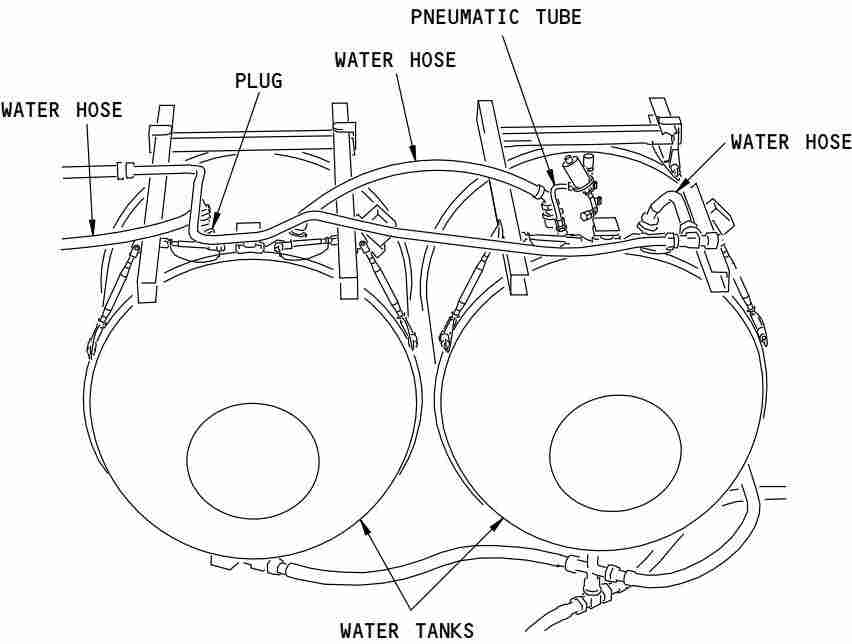

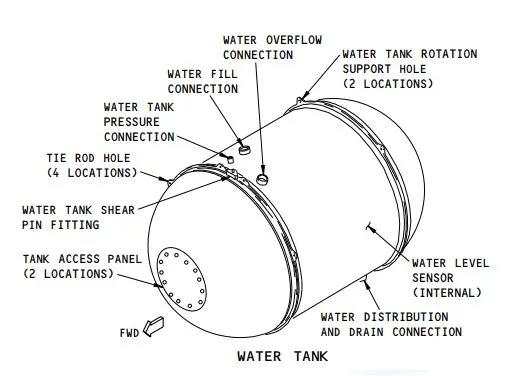

1. Onboard Water Tanks

Aircraft are equipped with dedicated onboard water tanks that store potable water. These tanks are carefully designed and constructed to meet stringent health and safety standards. Regular maintenance and sanitization are crucial to ensure the water remains free from contaminants.

These tanks have capacity to serve hundred’s of people onboard. In a Boeing 777-200/300 aircraft has total three potable water tanks where each of them has the capacity to hold 120 gallons (454 liters).

2. Water Filtration and Treatment

Before reaching the taps or galleys, the water undergoes a filtration and treatment process. Advanced filtration systems are employed to remove impurities and ensure that the water meets quality standards. Some systems may also incorporate chemical treatments to disinfect the water and maintain its purity.

3. Pressurized Water Distribution

The potable water system includes a pressurized distribution system to deliver water to different areas of the aircraft where it is needed. This ensures that passengers and crew have access to clean and safe drinking water, as well as water for handwashing in lavatories and for use in galleys.

4. Water Quantity Monitoring

Aircraft are equipped with systems to monitor the quantity of potable water on board. This helps the crew manage water usage and ensures that there is an adequate supply for the duration of the flight.

5. Ground Servicing

During ground servicing, ground crews replenish the aircraft’s potable water supply and perform checks to ensure the system’s integrity. This involves connecting the aircraft to a potable water source at the airport, filling the onboard tanks, and conducting routine inspections.

Maintaining a reliable and sanitary potable water system is essential for meeting the hygiene and hydration needs of passengers and crew and the regulations of aircraft water and waste system.

Stringent regulations and guidelines are in place to ensure the quality and safety of the water throughout its journey from ground servicing to consumption on board. Regular inspections, testing, and maintenance procedures are carried out to uphold the standards of the potable water system in aviation.

Aircraft Waste System

The waste system in an aircraft is designed to manage and dispose of both liquid and solid waste generated during a flight. This system ensures the cleanliness and hygiene of the aircraft’s lavatories while maintaining the comfort of passengers and the efficiency of the overall operation. Here is an overview of how the waste system works in an aircraft:

1. Lavatory Design

Lavatories on aircraft are compact and specially designed to maximize space efficiency. They feature toilet bowls equipped with either vacuum or suction systems. These systems are crucial for minimizing water usage and efficiently disposing of waste.

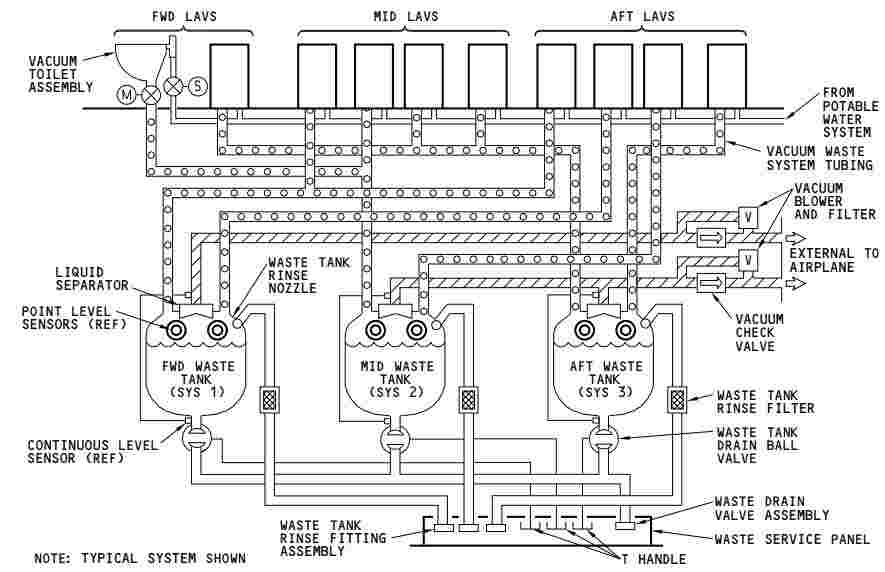

2. Vacuum or Suction Systems

Instead of relying on gravity, which is the conventional method in households, aircraft lavatories often use vacuum or suction systems. These systems create a pressure difference, effectively pulling waste into the waste storage tanks. Vacuum toilets use significantly less water than their gravity-fed counterparts, contributing to overall weight savings on the aircraft.

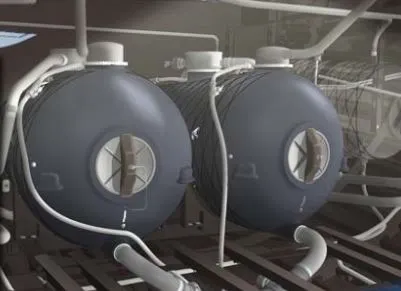

3. Waste Storage Tanks

The waste from lavatories is directed into sealed and airtight waste storage tanks located in the lower sections of the aircraft. These tanks are designed to prevent odors from escaping and to maintain a sanitary environment on board.

4. Separation of Solid and Liquid Waste

Some waste systems are equipped with mechanisms that separate solid waste from liquid waste within the lavatory itself. This separation facilitates more efficient processing and disposal.

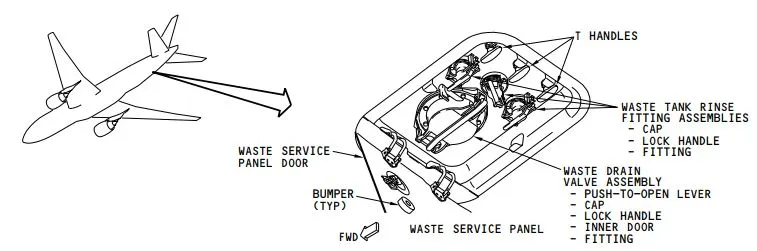

5.Ground Servicing

When the aircraft is on the ground, ground servicing crews undertake the task of emptying the waste storage tanks and replenishing necessary supplies. This process is part of the routine turnaround services provided by ground crews between flights.

6. Disposal at Airports

Waste collected in the storage tanks during flight is typically disposed of at the airport. Ground servicing equipment is used to connect to the aircraft’s waste system, and the waste is safely removed and treated according to local regulations and environmental standards.

7. Regulatory Compliance

The design and operation of aircraft waste systems are subject to strict regulations and standards imposed by aviation authorities. These regulations ensure the safe and environmentally responsible disposal of waste generated during flight.

In summary, the waste system in an aircraft is a sophisticated engineering solution that efficiently manages both liquid and solid waste, contributing to the overall comfort, hygiene, and operational efficiency of air travel. Regular maintenance and compliance with aviation regulations are essential to ensuring the proper functioning of the waste system throughout the lifespan of an aircraft.

Conclusion

In the complex world of aviation, where every ounce matters, aircraft water and waste systems play a crucial role in ensuring passenger comfort and operational efficiency. As technology advances, these systems continue to evolve, meeting the demands of an industry that seeks to balance innovation, efficiency, and environmental responsibility in the skies.